Supplementary Cementitious Materials (SCMs) - Calcined Clay Cement.

Calcined Clay: Revolutionizing Cement Additives

Calcined Clay (CC) is gaining popularity as a Supplementary Cementitious Materials (SCMs) with a rich history dating back over 25,000 years.

Produced by burning special clays at certain conditions, CC offers remarkable benefits when correctly engineered and integrated into cement production.

“At CEMTECH, we aim to be the turnkey contractor of your Calcined Clay Factory.”

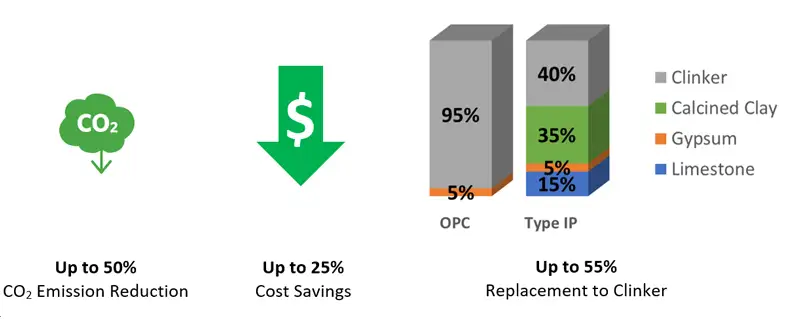

Using Calcined Clay as an additive in cement results in several advantages:

- Lower CO₂ Emissions: Significantly reduces carbon emissions per ton of cement produced.

- Cost Efficiency: Considerably lowers the overall cost of cement production.

- Strength and Durability: Maintains similar compressive strength to traditional cement while offering higher resistance to chemicals and weathering.

- Enhanced Performance: Reduces permeability, enhancing the longevity and resilience of the cement.

Standards now allow for up to 55% usage of Calcined Clay in some cement formulations, paving the way for a more sustainable and cost-effective future in the cement industry.